Bottel Contract Cnc Shop: Unlocking Precision and Expertise

Introduction to Bottel Contract Cnc Shop

Bottel Contract Cnc Shop stand at the forefront of precision engineering, offering tailored CNC machining solutions under specific contractual agreements. These shops specialize in turning design blueprints into tangible, high-precision components, crucial for industries where accuracy is paramount. By utilizing advanced CNC (Computer Numerical Control) technology, Bottel shops cater to complex requirements across sectors like aerospace, automotive, and healthcare, ensuring that every machined part meets stringent quality standards.

What Exactly is a Bottel Contract CNC Shop?

A Bottel Contract CNC Shop specializes in Computer Numerical Control (CNC) manufacturing under specific contractual agreements, focusing primarily on precision machining tasks. This type of setup typically caters to clients needing specialized parts produced with high accuracy and repeatability, often for critical applications in various industries like aerospace, automotive, and medical devices.

Diving into the Capabilities of Bottel CNC Shops

Key Features of Modern CNC Machining Centers

CNC shops equipped with state-of-the-art technology offer an array of features that enable the production of complex parts with fine tolerances. These features often include advanced software for precise control, multi-axis machining capabilities, and adaptive tools that adjust parameters in real-time for optimal results.

Advantages of Partnering with a CNC Machining Specialist

Choosing a contract-based CNC shop like Bottel allows clients to leverage high-level technical expertise and sophisticated machinery without the overhead costs of maintaining these resources in-house. This partnership can lead to faster production times, cost savings, and access to specialized technical knowledge.

Ensuring Longevity and Performance

Maintenance Protocols for High-Performance CNC Machines

Regular maintenance is crucial for the longevity and reliability of CNC machinery. This includes routine checks, scheduled servicing of critical components, and immediate attention to any signs of wear or malfunction, ensuring consistent performance and preventing costly downtime.

Safeguarding Operations: Safety Protocols in CNC Machining

Operating CNC equipment involves stringent safety measures to protect operators and machinery. This includes training on proper machine use, wearing protective gear, and implementing emergency procedures to handle potential hazards efficiently.

Operational Insights and Problem-Solving

Exploring Applications of CNC Technology in Challenging Environments

CNC machining is versatile, supporting tasks ranging from creating intricate medical implants to robust aerospace components. Its precision and adaptability make it ideal for producing highly specialized parts required in extreme conditions.

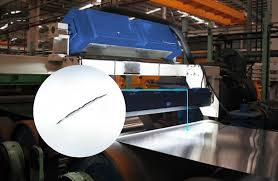

Common Setbacks in CNC Operations and Solutions

Even with advanced technology, CNC machines can encounter issues like tool wear, programming errors, and material inconsistencies. Addressing these challenges quickly is vital, often requiring skilled technicians to perform troubleshooting and adjustments.

Expert Tips for Maximizing CNC Machine Efficiency

Maximizing the efficiency of CNC machines is vital for maintaining competitive edge and ensuring high-quality output. Here are several expert tips to enhance your CNC operations:

Continuous Training: Regular training for operators keeps them updated on the latest machining techniques and safety protocols, ensuring that the CNC shop runs smoothly and efficiently.

Regular Calibration: Regularly calibrate your CNC machines to maintain accuracy. This ensures that machining processes remain precise, thereby reducing waste and increasing the reliability of the output.

Tool Maintenance: Implement a rigorous maintenance schedule for your tools. Well-maintained tools cut more efficiently, last longer, and can prevent damage to both the workpiece and the machine.

Optimize Cutting Conditions: Adjust and optimize cutting speeds, feed rates, and the cooling system according to the material being machined and the specific tooling used. This can significantly improve the lifespan of tools and the quality of finishes.

Use High-Quality Materials: Quality input leads to quality output. Using high-grade materials can reduce issues like tool wear and tear, and improve the overall quality of the finished product.

Implement Lean Manufacturing Principles: Streamline your operations by adopting lean manufacturing techniques. This can help reduce waste, minimize downtime, and improve overall operational efficiency.

Conclusion

Bottel Contract CNC Shops play an indispensable role in modern manufacturing by providing specialized, precision machining services. Through advanced technology and expert craftsmanship, these shops help businesses achieve exceptional quality in their products. By following best practices and continually seeking ways to improve machine efficiency, Bottel CNC Shops not only meet but exceed the rigorous demands of today’s manufacturing challenges, proving themselves as pivotal partners in the industrial landscape.

FAQS

1.What distinguishes Bottel Contract CNC Shops in the machining industry?

Bottel CNC Shops excel in delivering high-precision parts under contractual agreements, leveraging cutting-edge technology and skilled expertise.

2.How do Bottel Contract CNC Shops enhance production efficiency for clients?

These shops provide access to advanced machinery and technical skills, reducing overhead costs and speeding up production cycles for clients.

3.What safety measures are pivotal in Bottel Contract CNC operations?

They enforce strict safety protocols including comprehensive training, protective equipment, and emergency procedures to ensure operator and machine safety.

4.What types of industries benefit most from Bottel Contract CNC Shops?

Industries such as aerospace, automotive, and medical devices benefit greatly due to the need for precise, repeatable, and high-quality machining tasks.

5.How does regular maintenance impact the performance of CNC machines at Bottel Shops?

Regular maintenance ensures the machines operate at peak efficiency, prevents unexpected downtime, and extends the life of the equipment.

Post Comment