Enhancing Metal Sheet Inspection: Overcoming Challenges with AI-Powered AOI Systems

In the realm of manufacturing, metal sheet inspection is pivotal to ensuring product quality, structural integrity, and compliance with industry standards. However, traditional inspection methods often encounter challenges that can impede efficiency and accuracy. The integration of Automated Optical Inspection (AOI) systems, powered by machine vision technology, offers a transformative solution to these challenges. This article explores the common defects in metal sheets, the inherent challenges in their inspection, and how AOI systems, utilizing advanced machine vision, address these issues.

Common Defects in Metal Sheets

Metal sheets are susceptible to various defects arising during manufacturing, handling, or storage. Key defects include:

- Surface Imperfections: Scratches, pits, and dents resulting from rolling, cutting, or transportation processes can affect both the aesthetic appeal and functionality of metal sheets.

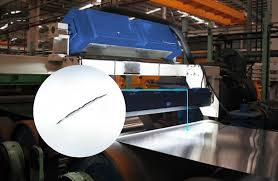

- Cracks and Fissures: Stress during manufacturing or thermal fluctuations can lead to cracks, significantly weakening the metal sheet and potentially causing failures in application.

- Inclusions: Non-metallic impurities embedded within the metal during melting and casting processes can compromise structural integrity.

- Corrosion: Exposure to moisture and corrosive environments can lead to rust and other forms of corrosion, degrading the metal over time.

- Waviness and Flatness Issues: Non-uniform thickness or lack of flatness affects the suitability of metal sheets for specific applications.

Challenges in Metal Sheet Inspection

Inspecting metal sheets presents several challenges:

- Detection of Minute Defects: Microscopic surface and subsurface defects, such as cracks or inclusions, are difficult to detect with conventional inspection methods.

- Variability in Material Properties: Different metals and alloys have unique characteristics, such as reflectivity and texture, affecting inspection accuracy.

- High-Speed Production Lines: Manual inspection struggles to keep pace with high-speed production, leading to potential oversight of defects.

- Subjectivity in Manual Inspection: Human inspectors may have inconsistent assessments due to fatigue or varying judgment, leading to unreliable quality control.

AOI Systems: Addressing Inspection Challenges

Automated Optical Inspection systems, leveraging machine vision system, offer precise and efficient solutions to these challenges:

- High-Resolution Imaging: Advanced cameras capture detailed images, enabling the detection of minute defects that are often missed by the human eye.

- Consistency and Repeatability: AOI systems provide uniform inspection criteria, eliminating the subjectivity inherent in manual inspections.

- Integration with Production Lines: Seamless integration allows for real-time inspection without disrupting manufacturing processes, ensuring immediate identification and correction of defects.

- Data Collection and Analysis: AOI systems collect comprehensive data, facilitating trend analysis and continuous improvement in manufacturing processes.

Implementing AOI Systems with Machine Vision

For successful integration of AOI systems in metal sheet inspection, consider the following:

- Customization: Tailor the AOI system to accommodate specific metal types and defect types, ensuring accurate detection across various materials.

- Illumination Control: Proper lighting is crucial for accurate image capture; AOI systems should include adjustable illumination to handle different surface finishes and textures.

- Software Algorithms: Advanced image processing algorithms enhance defect detection capabilities, allowing the system to distinguish between acceptable variations and actual defects.

- Training and Calibration: Regular calibration and training ensure the AOI system maintains high accuracy and adapts to any changes in the production environment.

Benefits of AOI Systems in Metal Sheet Inspection

Integrating AOI systems equipped with machine vision technology yields significant advantages:

- Enhanced Quality Assurance: Accurate and consistent defect detection ensures that only products meeting quality standards proceed, reducing the risk of failures in the field.

- Increased Throughput: Automated inspection keeps pace with high-speed production lines, minimizing bottlenecks and maintaining efficiency.

- Cost Reduction: Early detection of defects reduces waste and rework costs, contributing to overall cost savings.

- Compliance with Standards: AOI systems help maintain compliance with industry standards by ensuring consistent quality control.

The challenges inherent in metal sheet inspection necessitate advanced solutions that traditional methods often fail to provide. The implementation of AOI systems powered by machine vision technology addresses these challenges effectively, offering precise, consistent, and efficient inspection processes. By embracing these technologies, manufacturers can enhance product quality, optimize production efficiency, and maintain a competitive edge in the industry.

Post Comment